The Challenge: The piano plate, also known as the frame or harp, is a crucial structural component of a piano, providing the necessary support for the immense string tension. Typically made of cast iron, the plate ensures stability and durability while allowing the instrument to produce rich, resonant tones. It is carefully designed with precise contours and openings to accommodate the strings, soundboard, and other internal components.

A renowned musician & instrument maker wanted to re-design piano plate to improve the sound of the piano. However, there was no CAD model or drawing of the existing piano plate available to him to re-design the existing piano plate and work with a manufacturer to produce his new design.

Piano Plate (example)

The Solution: Designer & Creator of new piano plate contacted V3D Technologies and explained the issue and required deliverables. Experts at V3D Technologies had the perfect solution for this problem. Since the piano plate measures about 8ft x 5ft and weighs a few hundred pounds, the best solution was to scan the piano plate on-site. With our certified metrology grade laser 3D scanner, we arrived on-site for the first step. Existing piano plate was accurately converted from physical to digital by 3D Laser Scanning both sides of the piano plate.

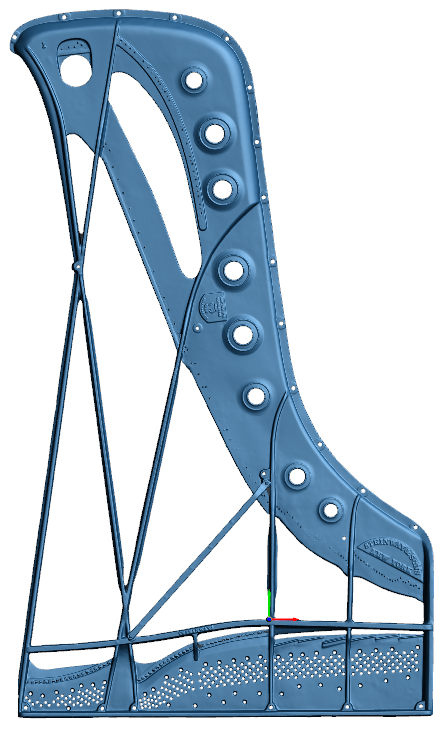

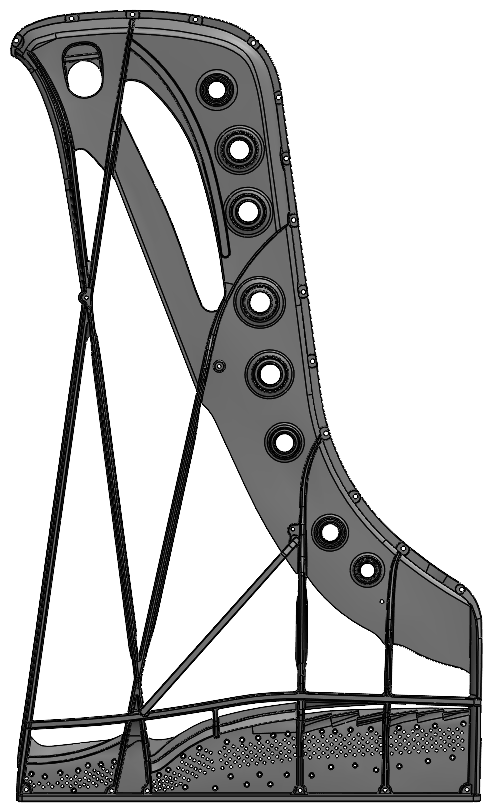

Polygon Model (scanned mesh) of Piano Plate (front)

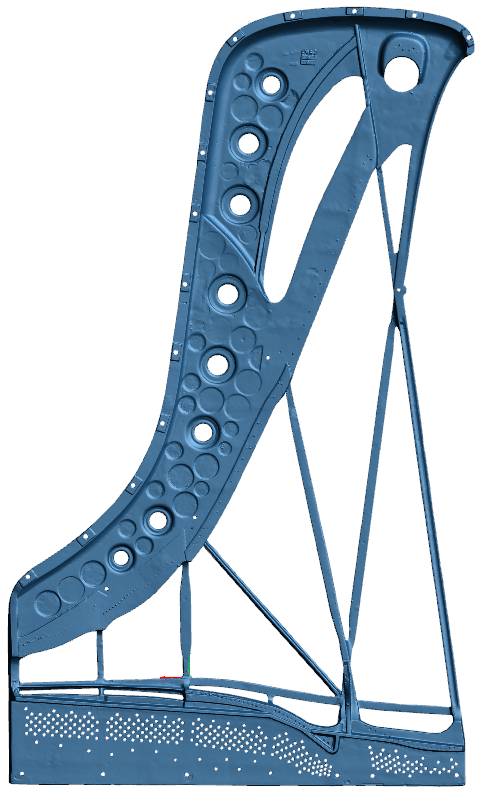

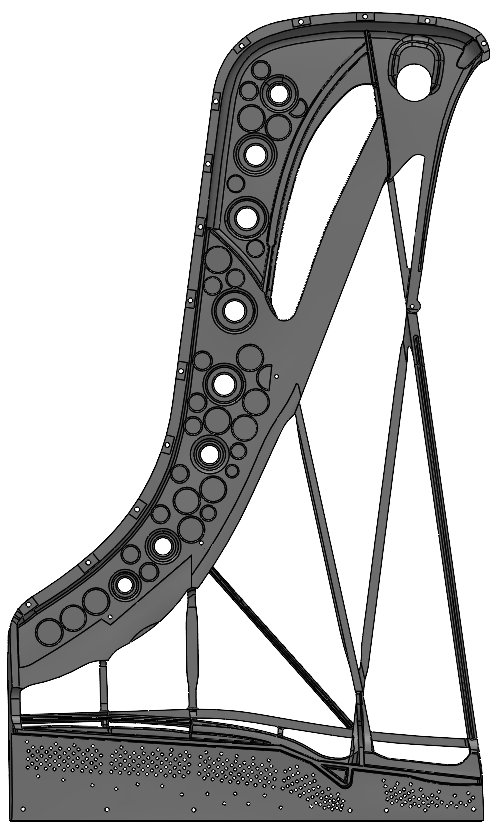

Polygon Model (scanned mesh) of Piano Plate (back)

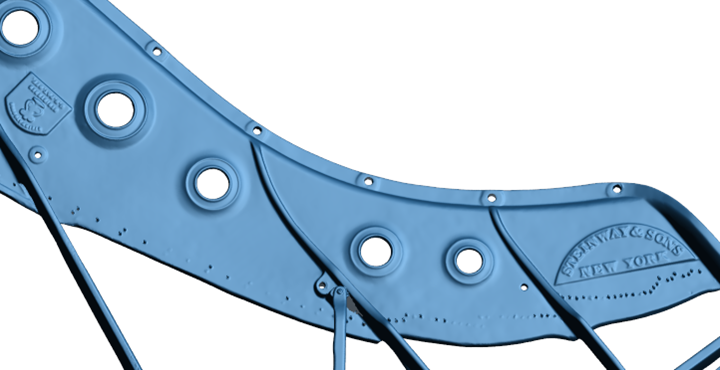

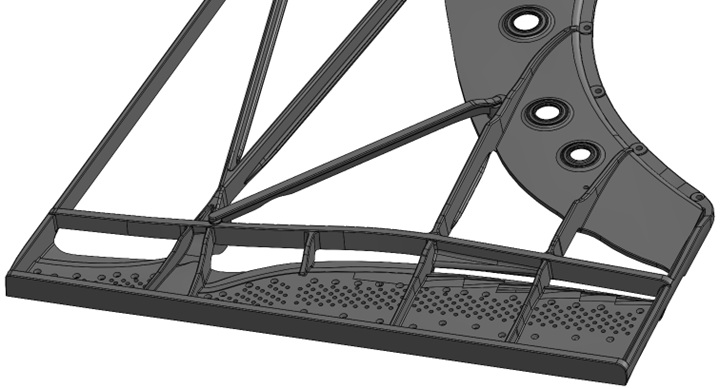

Polygon Model (scanned mesh) of Piano Plate (details captured)

The polygon model generated by the scanner was aligned to the global coordinate system in VXmodel software.

Next, we brought the aligned polygon model in Geomagic Design X Scan to CAD Reverse Engineering software. Design X allows to create accurate parametric CAD model using polygon model as a template. Using advanced surfacing and solid model creation steps, CAD model of piano plate was created.

CAD Model of Piano Plate

CAD Model of Piano Plate

CAD Model of Piano Plate

Conclusion: CAD model of piano plate by V3D Technologies was used to re-design the piano plate. 3D scanning by V3D Technologies can be a useful tool for musical instrument makers, restorers, and researchers. 3D scanning can also be used to create custom-fitted accessories for instruments. For example, a musician could have a mouthpiece or other accessory 3D scanned and then use the digital model to create a customized piece that fits their specific needs.

Overall, 3D scanning can be a valuable tool for those working with musical instruments, allowing for greater accuracy, efficiency, and customization in their work. V3D Technologies is your go-to partner for accurate 3D scanning and scan-to-CAD of your favorite musical instruments.