In the automotive industry, precision and accuracy are paramount. From designing intricate components to ensuring safety standards, every aspect requires meticulous attention. This is where 3D metrology plays a crucial role. By utilizing advanced measurement technologies and techniques, automotive manufacturers can optimize performance, enhance safety, and maintain high-quality standards. In this blog, we will delve into the applications and benefits of 3D metrology in automotive design and manufacturing, highlighting its impact on performance optimization and safety enhancement.

Designing with Precision

3D metrology enables automotive designers to create precise and complex components with exceptional accuracy. By utilizing technologies such as coordinate measuring machines (CMMs) and laser scanning, designers can capture detailed measurements of surfaces, curves, and contours. This ensures that each component meets precise specifications, allowing for seamless integration, improved functionality, and reduced assembly issues.

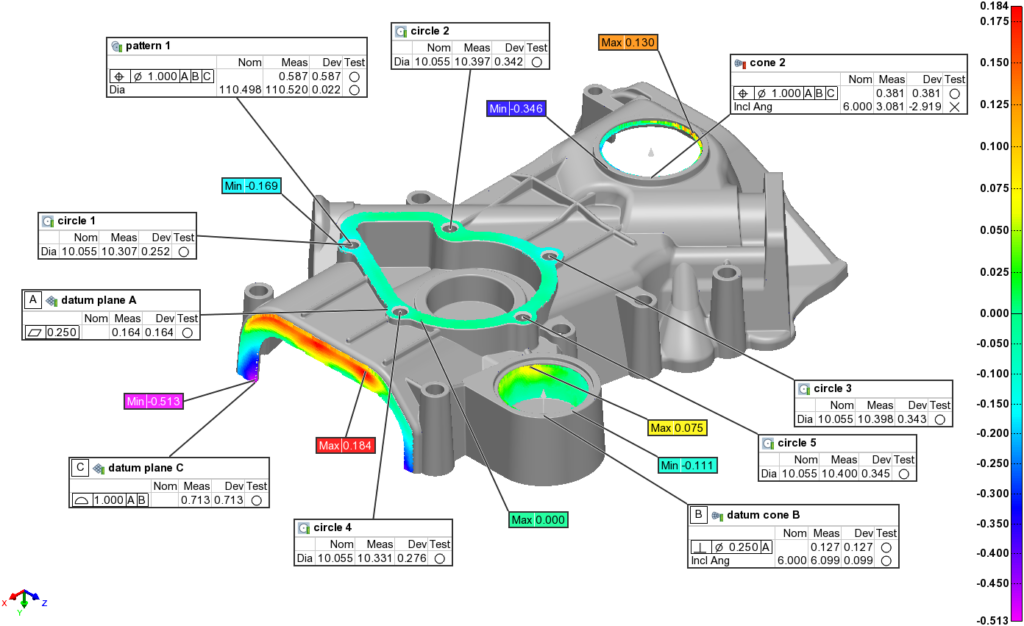

Quality Assurance and Control

The automotive industry places a strong emphasis on quality control to ensure vehicles meet rigorous safety and performance standards. 3D metrology plays a vital role in this aspect by providing comprehensive inspection and verification of critical components. Through techniques like laser 3D scanning, optical measurement systems and computed tomography (CT), manufacturers can identify defects, deviations, or inconsistencies in components, enabling timely corrections and maintaining high-quality standards.

Performance Optimization

3D metrology enables automotive manufacturers to analyze and optimize the performance aspects of vehicles. By conducting detailed measurements and analyses, engineers can assess factors such as aerodynamics, vehicle dynamics, and structural integrity. This data-driven approach allows for precise adjustments, leading to improved fuel efficiency, better handling, and overall performance enhancement.

Safety Enhancement

Safety is a top priority in the automotive industry, and 3D metrology plays a vital role in ensuring that vehicles meet stringent safety regulations. By conducting accurate measurements and simulations, manufacturers can assess crashworthiness, structural strength, and occupant safety features. This enables the development of safer vehicles by identifying potential weaknesses and making necessary design improvements.

Advancements and Future Trends

The field of 3D metrology is continually advancing, with new technologies and techniques emerging rapidly. This includes advancements in non-contact measurement systems, portable metrology solutions, and real-time data analysis. Integration of artificial intelligence (AI) and machine learning further enhances the capabilities of 3D metrology, enabling faster and more accurate measurements.

When it comes to tackling intricate 3D metrology challenges, V3D Technologies stands out with its team of highly skilled professionals who possess the expertise needed to deliver exceptional results.