3D Metrology Services – A new dimension to Dimensional Analysis and Quality Control

Scan to Inspect for Industry 4.0

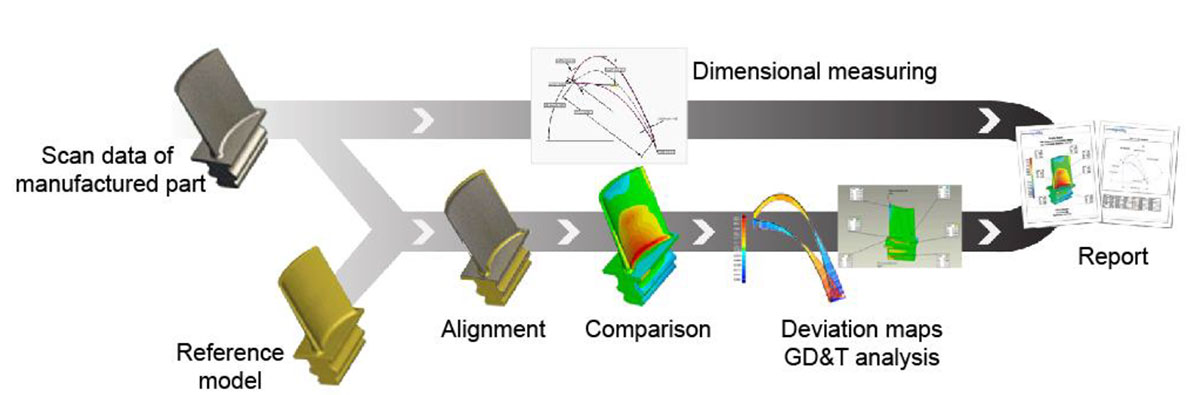

3D Metrology is the scientific study of the measurements of a physical object. It includes the precise measuring of tools, fixtures, and machined components in manufacturing. Conducting 3D Metrology in its basic form is to acquire an object’s geometrical data accurately in the x, y, z-axis. Traditionally, these measurements are often acquired using a coordinate measuring machine (CMM) which typically is programmed to pick only a few points on the surface of a part and offers text-based reports. However, the modern approach for 3D Metrology is to 3D scan an object which acquires thousands and millions of accurate points across a part for comprehensive inspection using CAD-based 3D Metrology software.

Precision, Speed, Detail & Traceability

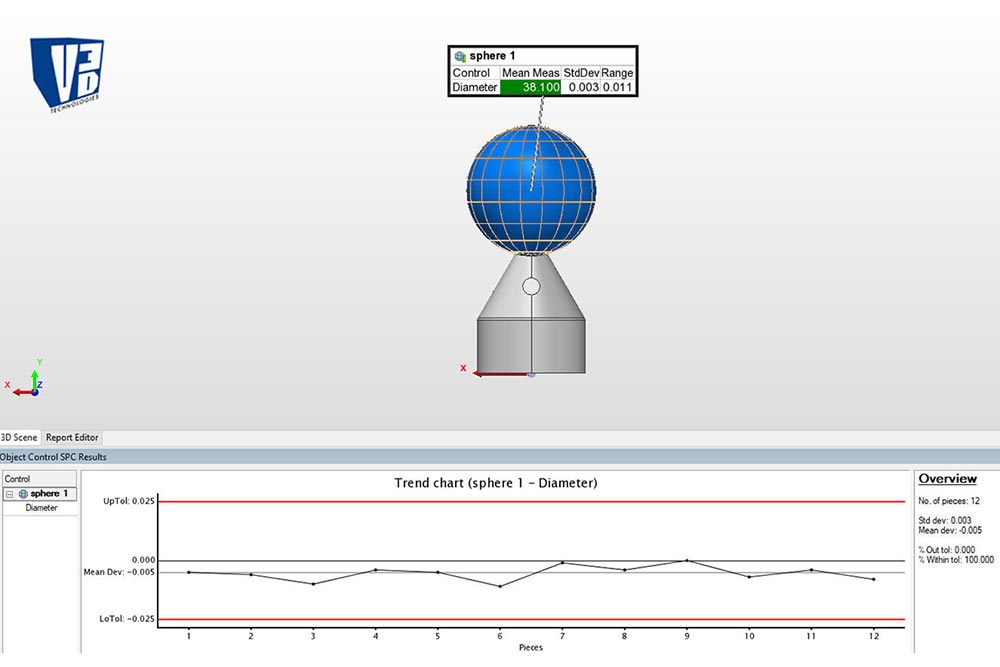

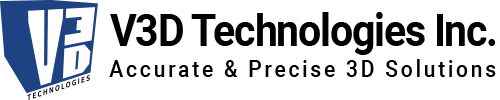

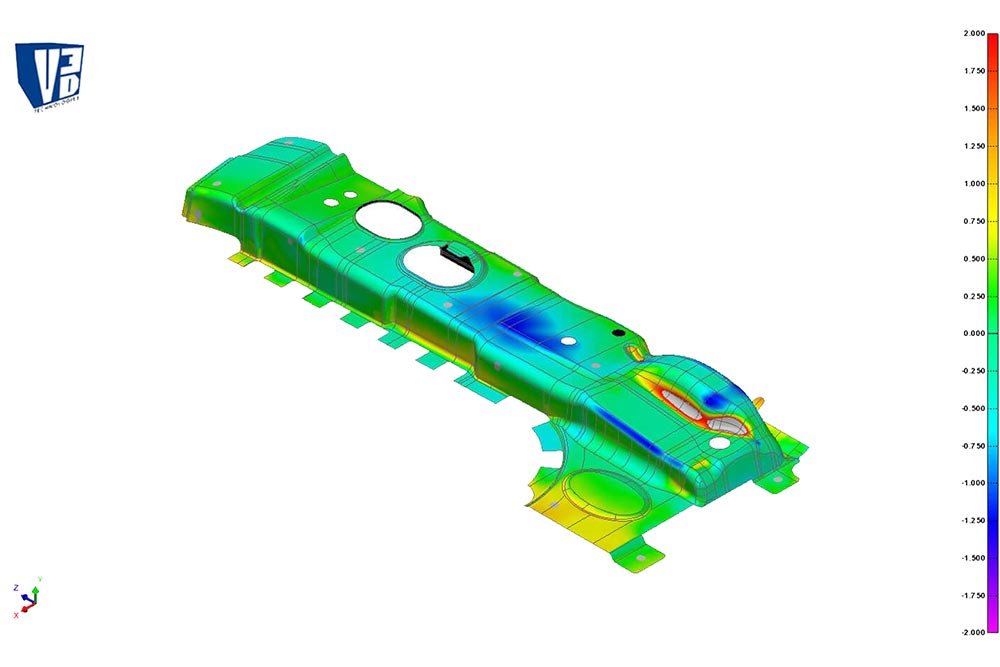

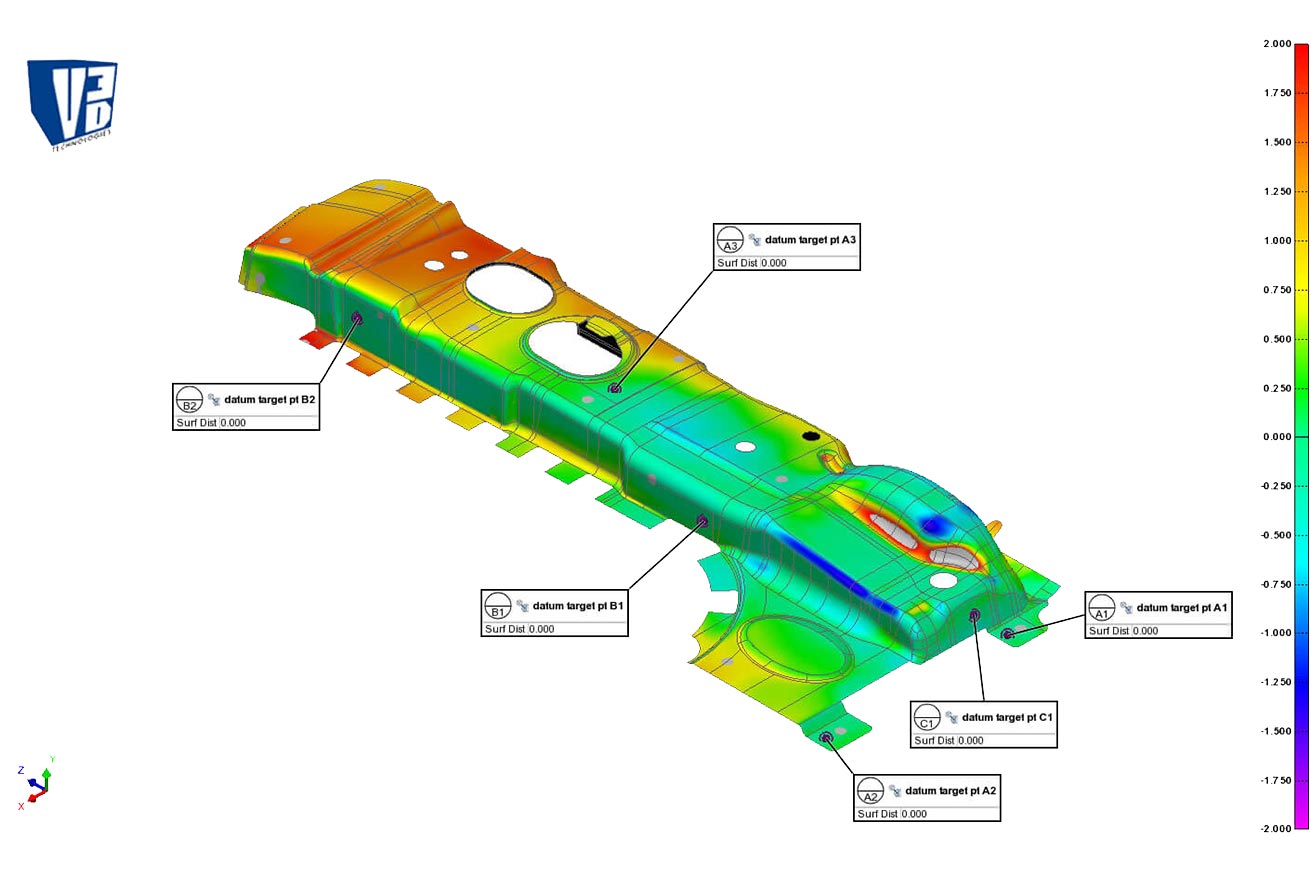

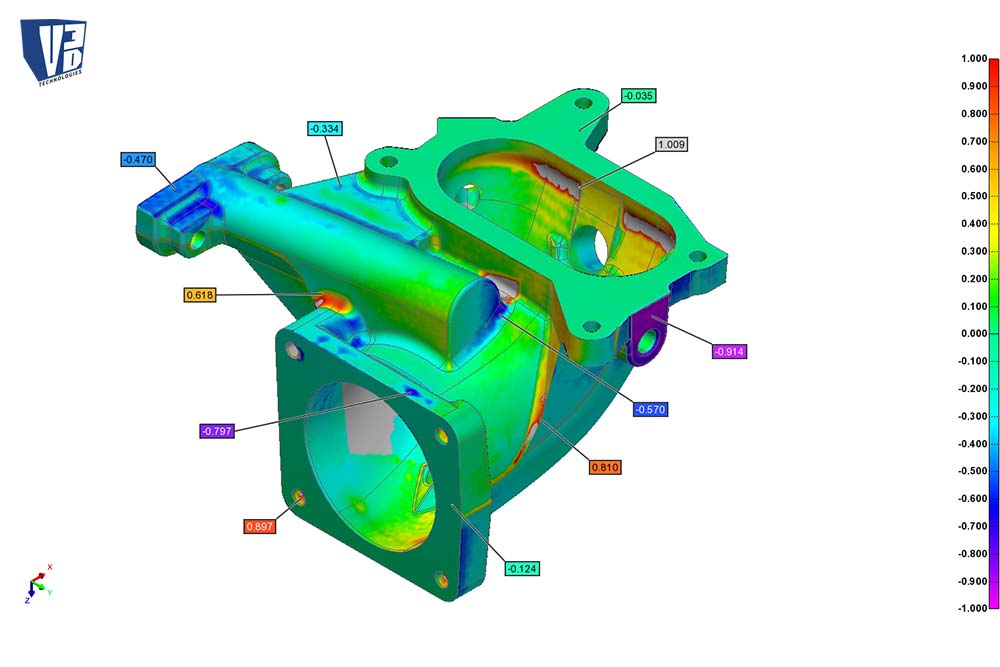

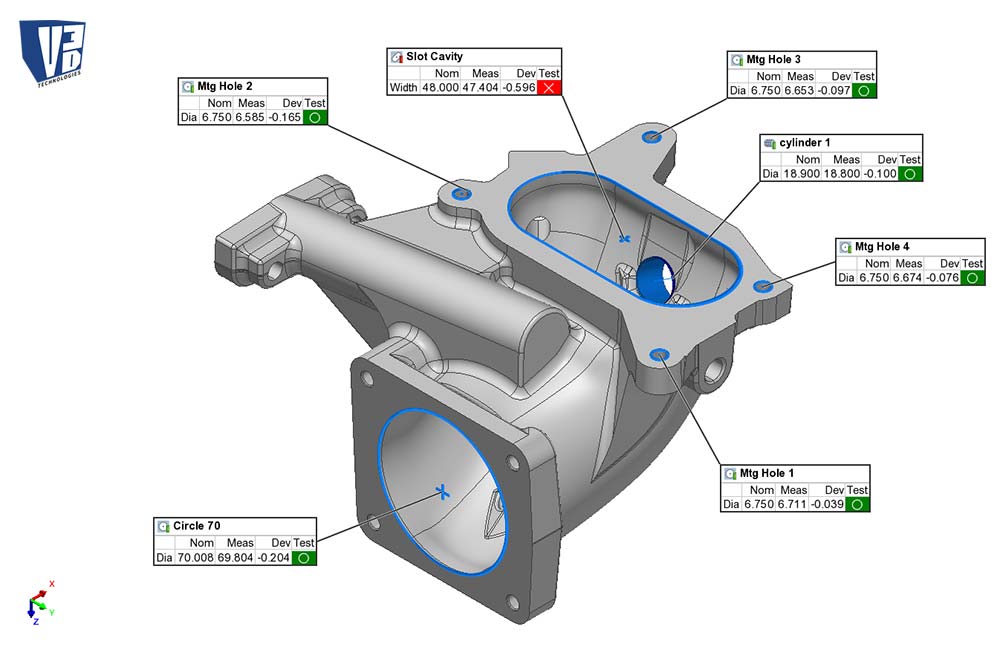

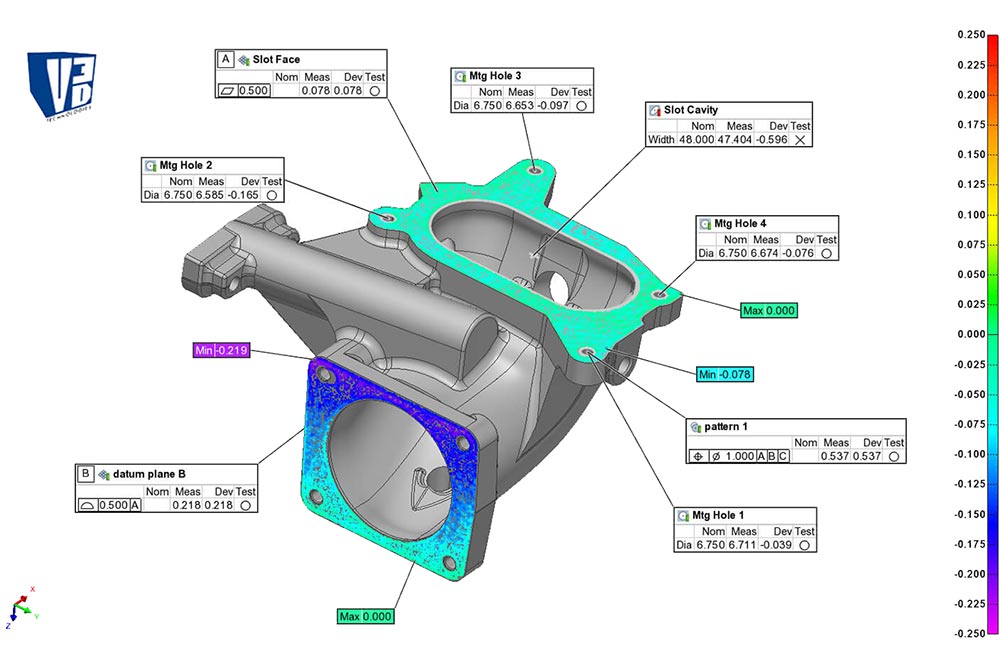

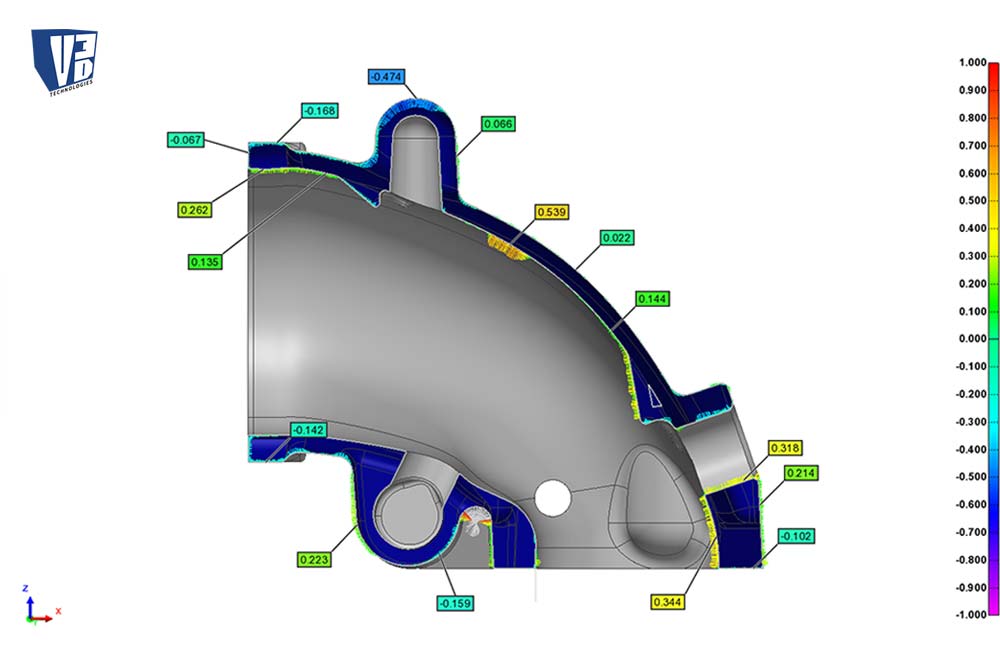

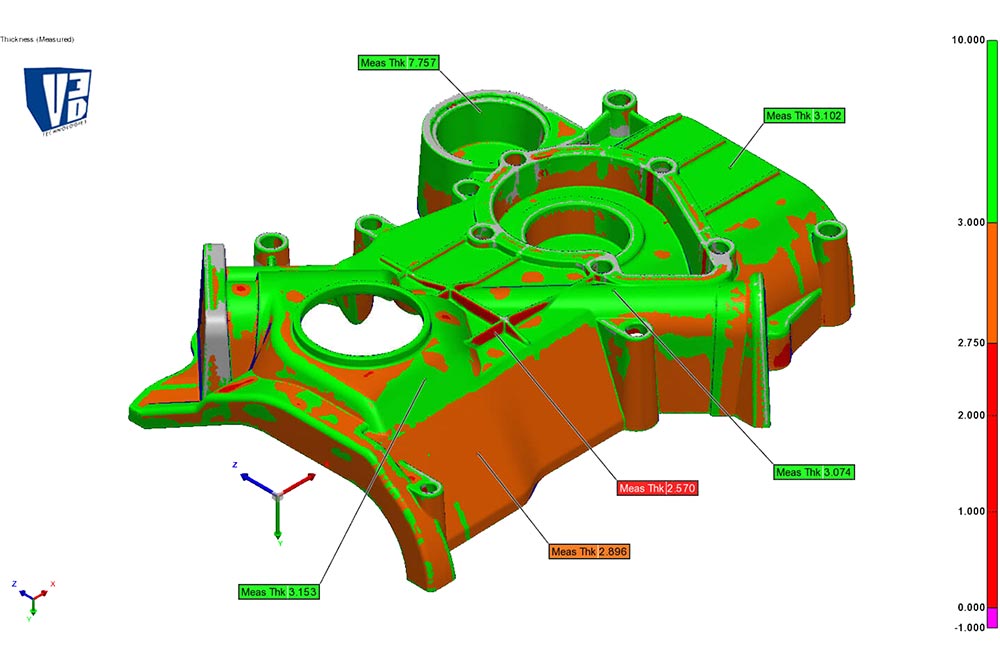

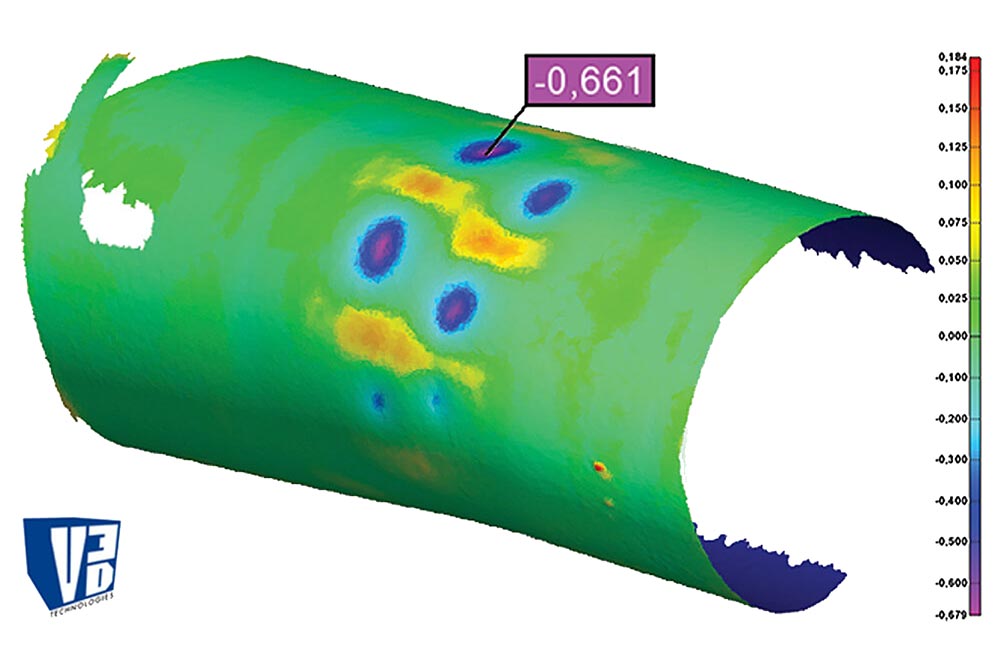

V3D Technologies uses Polyworks Inspector 3D Metrology software for dimensional analysis and quality control. It offers 3D scan to CAD deviation analysis, which is a tried-and-true approach for evaluating the precision and quality of a wide range of physical objects. This method can be used to examine newly manufactured parts or to check wear and deterioration on existing parts. When the surface features and other geometry are out of tolerance, this method shows differences between the 3D scan and the CAD model. Based on the parametric concept, which forms the underlying foundation for every function, Polyworks Inspector ensures that all process steps are traceable, thus guaranteeing process reliability for measuring results and reports.

3D Metrology Workflow

With its mathematical algorithms certified by PTB (Physikalisch-Technische Bundesanstalt),

Polyworks Inspector offers a suite of inspection functions such as:

Surface Best Fit

Measurement Object Best-Fit including Alignment from Features, Datum Targets, Surface Points, Edge Points etc.

Deviation Analysis using Color Map

Feature-Based Dimensioning

Smart GD&T based on latest ASME & ISO Standards

Cross-Section Analysis

Wall Thickness Analysis

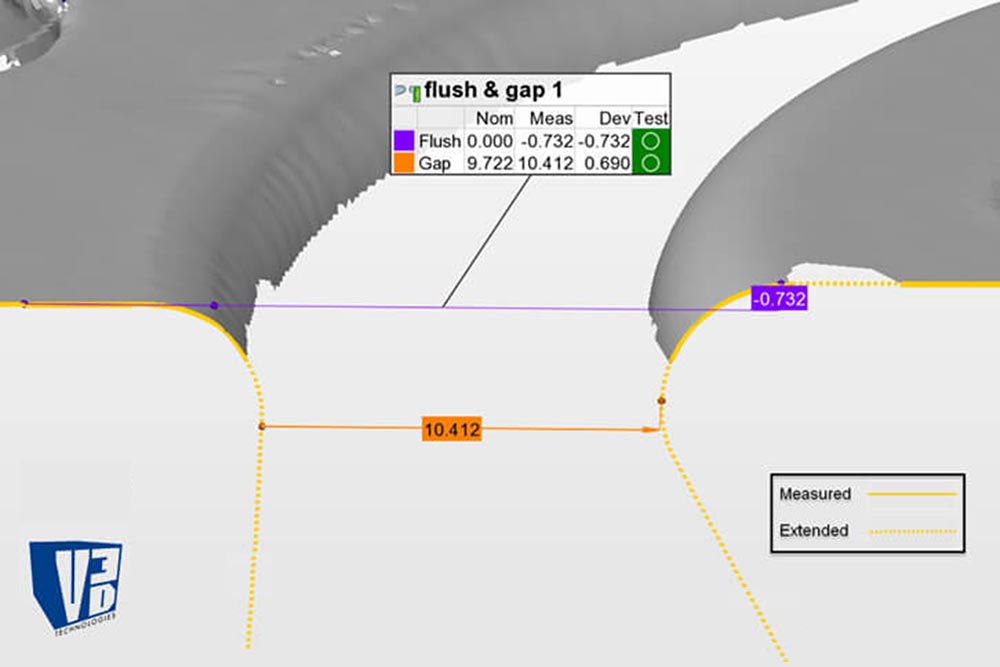

Flush & Gap Gauging

Surface Defect Analysis