3D Scanning for Tool and Die Industry

Utilizing 3D scanning techniques can offer significant benefits when inspecting, re-building and analyzing tools and dies in the manufacturing industry. By generating precise 3D digital models of these components, manufacturers can conduct thorough inspections, detect signs of wear or damage, and even simulate the manufacturing process to enhance design optimization.

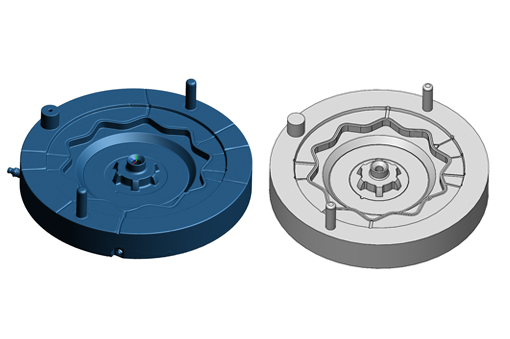

When it’s required to reproduce or modify existing tools and dies, 3D scanning can be invaluable. Often legacy tools have no 3D CAD model or tools and dies go through undocumented changes during their lifecycle. By 3D scanning the physical object, V3D Technologies produces a precise digital model and then takes it into a dedicated reverse engineering CAD software to create a new CAD model. This helps with reproducing or modifying the tool or die without requiring manual measurements or drawings

3D scanning allows for detailed inspections of tools and dies, enabling manufacturers to identify any dimensional non-conformance, defects, wear, or damage accurately. V3D Technologies uses metrology grade scanner that meets VDI/VDE 2634 part 3 standard and is ISO 17025 certified to produce high accuracy scans of tools and dies. By comparing the 3D scan data to the original design specifications in Polyworks Inspector, we can help manufacturers ensure that the tools and dies meet the required quality standards. Need to compare master cavity with rest of the cavities? We can accurately scan master cavity, convert it to reference data and compare other cavities to reference data (master cavity) and clearly show the differences on a color plot and numerically.