3D Scanning for Aerospace Industry

3D scanning technology plays a very crucial role in the aerospace industry, offering numerous benefits and empowering engineers with accurate data. It enables the precise and efficient creation of digital models for aerospace components, aiding in design and development, detailed dimensional analysis, testing, maintenance, and repair.

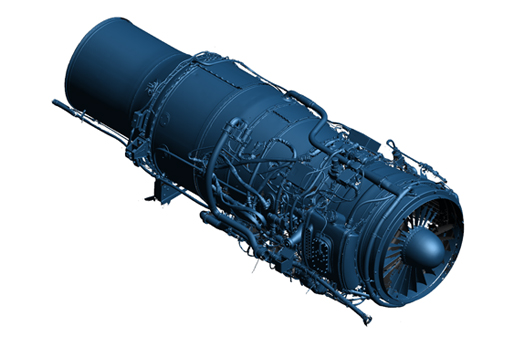

A primary advantage of 3D scanning in the aerospace industry is its ability to capture intricate geometries of complex parts like turbine blades and engine components. This accurate data facilitates detailed modeling, analysis, and simulation, contributing to improved performance and reliability. V3D Technologies uses high accuracy portable 3D scanner to accurately digitize aerospace components. Call us for on-site scanning or send your components to our facility for scanning. Using dedicated reverse engineering software, we can then create CAD model for any complex shaped component using accurate scan data. 3D scanning technology also enables the creation of replacement parts. By 3D scanning damaged or worn components, V3D Technologies can generate precise digital models and provide a watertight mesh that serve as a basis for manufacturing replacement parts using additive manufacturing techniques, such as 3D printing.

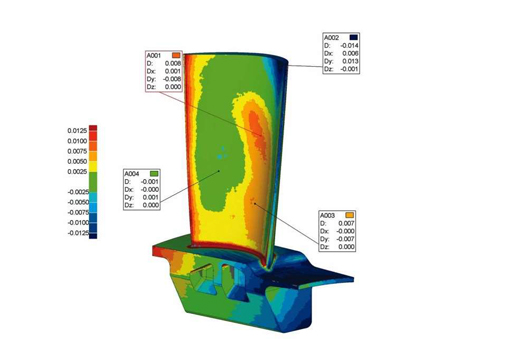

Another significant application of 3D scanning is the inspection of precision aerospace components for dimensional compliance, defects, or damage. After scanning the parts using our metrology grade scanner that meets VDI/VDE 2634 part 3 standard and is ISO 17025 certified, V3D Technologies can perform traceable 3D metrology using Polyworks Inspector to help identify potential issues such as dimensional non-compliance, surface defects, etc.