Precision and efficiency are paramount in the rapidly evolving world of construction and infrastructure development. The Mechanical, Electrical, and Plumbing (MEP) industry, which plays a pivotal role in building design and construction, is no exception. In recent years, 3D scanning technology, including Lidar scanners, has been a game-changer, transforming how MEP professionals work. In this blog, we’ll delve into the benefits of 3D scanning for the MEP industry and how V3D Technologies Inc. is leading the way in revolutionizing MEP projects.

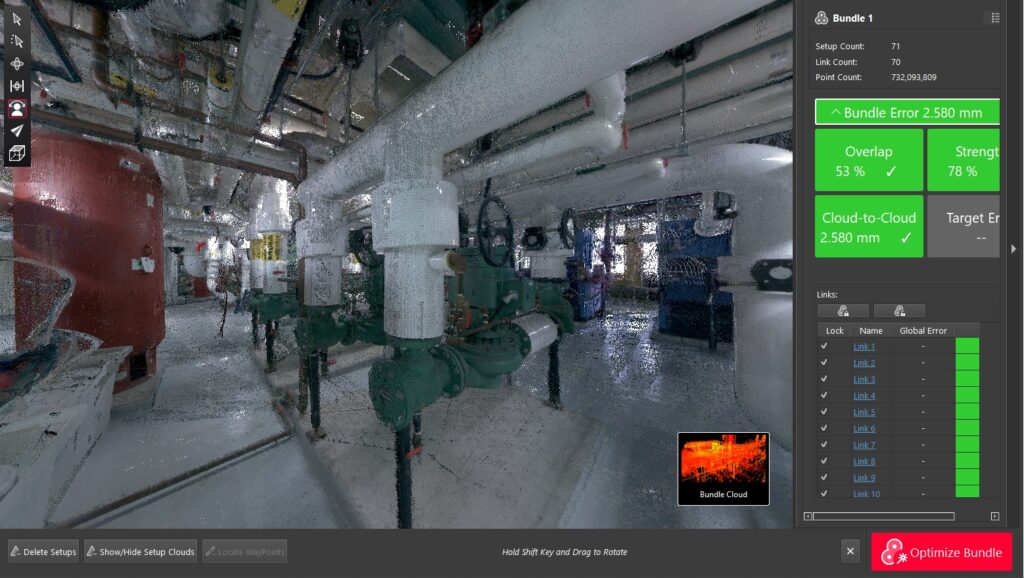

Enhanced Precision: Precision is the cornerstone of MEP projects. Traditional measurement methods can be time-consuming and prone to human error. With 3D scanning technology, such as LiDAR scanners, MEP professionals can capture detailed, high-precision measurements of the project site. This technology empowers the generation of precise 3D models that serve as the foundation for designing and planning MEP systems.

Streamlined Design and Planning: 3D scanning drastically reduces the time required for initial site assessment and data collection. LiDAR technology, in particular, can rapidly scan large areas, including complex MEP installations. This streamlined process allows engineers and designers to work with a comprehensive and accurate representation of the project site, resulting in faster and more efficient design and planning phases.

Clash Detection and Avoidance: One of the most significant advantages of 3D scanning in the MEP industry is its ability to identify clashes and conflicts in design early in the project lifecycle. With precise 3D models generated from scans, professionals can detect and resolve clashes between mechanical, electrical, and plumbing systems before they occur on-site, minimizing costly rework and delays.

Improved Communication and Collaboration: Effective communication and collaboration among stakeholders are crucial in MEP projects. 3D scanning technology facilitates better communication by providing a common, highly detailed visual representation of the project. It fosters collaboration among architects, engineers, contractors, and subcontractors, resulting in a smoother project workflow.

Reduced Risk and Cost Savings: Identifying and resolving issues during the planning and design phases, rather than during construction, significantly reduces project risk and saves costs. 3D scanning minimizes the likelihood of unforeseen challenges and changes, contributing to a more predictable and cost-effective project.

As-Built Documentation: 3D scanning technology allows for creating precise as-built documentation, helping MEP professionals verify that installations are accurate and comply with the original design. This documentation is invaluable for project owners and facility managers, aiding in maintenance and future modifications.

V3D Technologies Inc: Pioneering the Future of MEP

In the MEP industry, V3D Technologies stands at the forefront of 3D scanning technology, including LiDAR 3D scanning. Their cutting-edge solutions empower MEP professionals to harness the full potential of 3D scanning for enhanced precision, efficiency, and project success.

The MEP industry is evolving with the adoption of 3D scanning technology, particularly LiDAR scanners. Enhanced precision, streamlined design, clash detection, improved collaboration, reduced risk, and significant cost savings are just a few of the benefits that MEP professionals can enjoy. As industry leaders like V3D Technologies continue to innovate, the MEP industry’s future is characterized by even greater efficiency and precision, setting the stage for a new era of construction excellence.